In case you are into it, this is actually one of the plot lines in The Expanse (spoilers).

In case you are into it, this is actually one of the plot lines in The Expanse (spoilers).

I don’t have anything to add but I am glad someone posts this every week, I always find something new, so please keep it up :D

Shout out to Everything Smart Home, great YouTube channel as well!

Just to add my 2c, I just started using this the other day just as an quick UI for ollama and I was blown away at how many features it has and i think the interface is well done. It’s really a great tool so far and I’ll definitely be using it more going forward!

I know you solved it but for anyone that finds this later this feature/behavior is typically called “NAT Hairpin” in case you are looking for a setting to enable or disable, hope this helps!

Just to add what others have said, the temp you dry at is as important if not more important than time and different for each type of plastic. If you don’t have it hot enough (typically near the glass transition temperature of the plastic) then the moisture is not able to escape the plastic.

Cool project as well, I have wanted to do the same!

Ah yeah that is good, just making sure because it has caused me a lot of strange issues hah.

One thing that prob doesn’t matter but I usually dry PETG at 55 or 60, not sure how much of a difference that will make, 51 might be warm enough though. From what I have learned, it has to be warm enough that the moisture can escape the plastic (usually just below the glass transition temp) so you might try turning it up a bit if nothing else works because the moisture might not be escaping.

A lot of good avi e from others but definitely don’t discount drying it out, especially if you live somewhere that the air RH is over 20% as it will definitely suck it out of the air and act all kinds of odd in my experience.

Dang I thought it couldn’t be that bad but even the fist sentence is a struggle and seems to be incomplete let alone the first paragraph barely making any real sense at all.

This is a great list! Discovered a few new ones, thanks!

Lots of good recommendations here, my usual recommendation is that if you want 3d printing for a hobby to get a Bambu or similar because they just function out of the box for basically all materials. If you want 3d printing to be the hobby then a Prusa or Voron as others have said, way more tinkering to be had. Both are lots of fun though!

Hey not sure if I’m too late but there are a few places I have run across that I don’t see mentioned:

Also, your resume sounds a lot like mine, I have done a wide variety of things over the years. If you want someone to review your resume I am happy to, send me a DM or something. I’m not a developer but I have reviewed a lot of resumes for people and mentored all kinds of engineers, I am a principal level engineer in a related path though.

I just wanted to add this video to your comment because e-ink is so cool and this guy has a bunch of macro shots of the displays that are awesome and you can see the particles in the screen changing colors.

So cool!

Glad to help! Mixing colors shouldn’t be an issue, I have done it in the past, also have mixed PA and PA-CF in the past without issue. I bet you could even find a tent with a window and run a PTFE tube to a dry box outside the tent then you could pull the first color out and put the second one in without having to open the tent.

Also, just to say it out loud I would definitely test the strength of the layer adhesion (especially between the colors since they might have different additives) for anything structural, especially if you might get injured if it fails, just to be double safe heh.

Last, at least where I am, PA is significantly more expensive than ASA or PETG so might be worth looking at those for at least prototypes of the parts. For example, I typically use PLA to prototype ASA parts, has usually been fine to swap it out with just minor tolerance adjustments and it’s way cheaper to print 50 versions in PLA while I’m working out the design and then I print the final ones in ASA or whatever.

I have printed PA and tent idea will probably work but the other person is not kidding, PA is very finicky. Plan on printing PA directly from a dry box as even sitting on the printer will ruin a roll of it if you live somewhere with more than like 20% humidity outside, also make sure your dryer can reach 85c to dry out a spool of PA, even with a dry box I usually dry PA immediately before printing it. As others have mentioned, definitely consider ASA or PETG or maybe even PC (if that printer can print it) where you don’t really need the material properties of PA specifically.

The tent will also probably be important for maintaining temperature of the chamber more than the smell, nylon doesn’t have a ton of odor anyway. You may need to put a blanket on it, you probably won’t need a chamber heater since nylon needs like a 65c bed or more, just make sure to pre-heat the chamber first by turning the bed on, I usually let mine warm for 20 min or more. It is alap important to keep the temps stable as nylon also warps easily which can cause it to pop off the bed while printing too So make sure the tent is sealed and try not to open it.

Sounds like an interesting project though, best of luck!

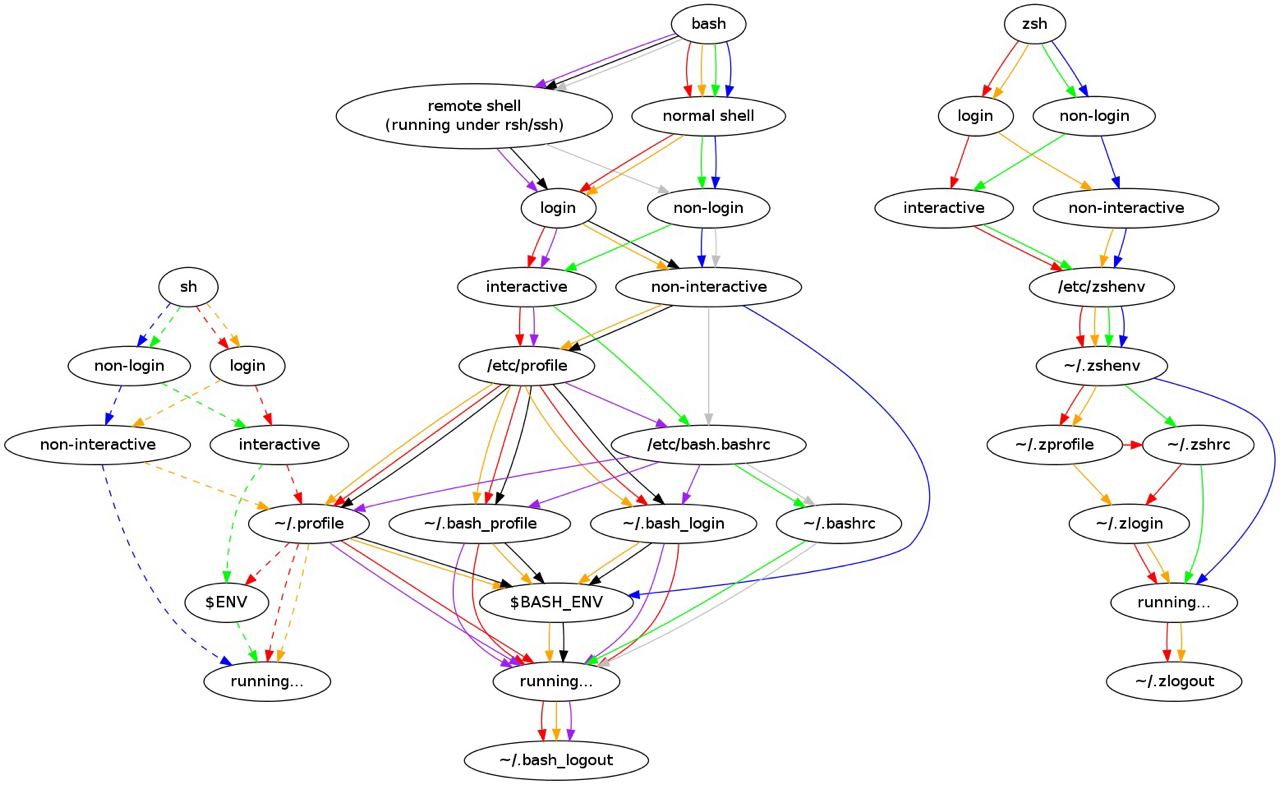

I found this diagram on SO at one point but I can’t find the post and it is the best explanation I have found for how all of the files work for bash and zsh, each color is an individual path of execution (eg, follow the red line).

Bottom line though, it only really matters if you are overriding something that is already defined, for example I tell my users to use zshrc and I provide defaults and common things in zprofile because zshrc is executed last when they login.

Right? It minorities blew my mind when I read it the first time and keeping that in mind has made my life so much easier overall, and definitely made it easier to describe to managers over the years.

This is great, also if you haven’t read it, you should read Makers Schedule, Managers Schedule by Paul Graham, it really helped me describe this concept to all of the managers I have had hah.

I am so glad you keep posting, your builds are beautiful and are an inspiration to me to make my builds look good so keep it up :D. I really like the roof on this one, might have to copy that for one of my factories.