Hi guys. Please check my previous post for any background questions, I don’t have it in me to go over everything again.

Long story short, I was having issues with clogging that were being caused by my hotend not reaching the reported temp. After a few days of troubleshooting and diagnosing the motherboard and Klipper settings, I gave up and decided the motherboard was faulty (even though I could not perform any tests to determine in) and bought an SKR mini. I got that all set up, and the printer has been working flawlessly since then.

Until now.

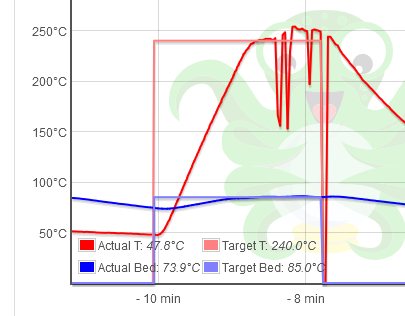

Same exact problem; one print goes perfectly fine, next print, failing to extrude by the 4th layer. I removed the clog, restarted the print, now can’t even extrude the priming line. Fearing the worst, I disassemble the hotend, try hand feeding filament, and once again I am unable to push more than a few centimeters through before it gets clogged up. A probe thermometer reads ~160C while Klipper reports 200C.

What could possibly be happening here? The board is an aftermarket replacement from a completely different company, so I doubt it’s a recurring manufacturer defect, but I have no idea what else can be causing this.

At this point I’ve spent so much time and money trying to fix this printer that I could almost buy a new one, but at this point I’m not convinced even that would solve the problem.

That’s super irritating, sorry you’re still dealing with it.

I’m thinking long shot items now;

I realise I’ve been focusing on the heat itself, but could your extruder be skipping? There’s no grinding or dust in the gears? In really bad cases they can chew into the filament itself, I’ve had it happen moreso after clearing a clog but it still can happen, cleaning it with air and lightly oiling the gear mesh is a decent start.

Don’t think it’s related but might be worth dropping your klipper configs, specifically around hotend stuff.

Have you tried totally new nozzles? Could have a very slight partial clog remaining that keeps showing up.

Do your part cooling fans blow directly on the block? 4th layer is about when that would kick in for my config with PLA, I have socks on mine and I run stealthburner hotends on both my voron and prusa so they blow below the block, but even then you can notice and definite change in cooling rate of a hot block.

I know I brought up intermittent breaks before, klipper by default looks to do 1s input smoothing on the thermistor to reduce sensor noise which could maybe hide it, but that’s unlikely, I’ve seen it on my printers

this was on the prusa when it was running marlin still, very obvious at this point but it was having clogging and printing issues before it started to trip thermal runaway.

this was on the prusa when it was running marlin still, very obvious at this point but it was having clogging and printing issues before it started to trip thermal runaway.

What sort of print speeds are you doing and do you happen to know the material your block is made of? 200 is cold to me for PLA, while I know its smack in the middle of a lot of manufacturers, personally run closer to 215, prusament’s profiles are 210 if I recall. Not something that’s going to suddenly cause you an issue though, only thought I could have is same temps with higher speeds/feedrates

Might be worth doing a cold pull to thoroughly clean the nozzle which prusa suggests pla works best for, or run cleaning filament through if you have it. i swear it’s just hot glue in filament form but man if it doesnt actually clean things up nicely when I use it for material changes.

Other thoughts, is your PID tune not aggressive enough? I’ve found that klipper will do its best to hit a target temp with minimal overshoot where marlin would run to a temperature, overshoot and then try to maintain it, if you’ve change anything in your setup at all I’d suggest retuning it with fans running at your regular fan speed, I do 250 at 50% as that’s around what I’ll use for abs and petg. Filament super dry? While wet filament can cause a bunch of other issues with print quality, I could totally see it contributing to clogging as well.

I really, really appreciate the time you’ve taken to try to help me, but I’m positive the hot end not reaching target temp is the issue. If I push filament against the outside of the heat block, it melts at a very slow rate, when it would normally instantly liquefy against the block.

I’ll drop my config file when I get home.

My temp chart, both before and after the issue started again, are near perfect flat lines. PID tuning done on current hardware.

My hotend has a fan blowing on the cooling block, and two part cooling fans.

There are no clogs/ obstructions throughout the hotend. New hardware has been tested (nozzles, heat throats)

Typically I print between 60-120mm/s depending on nozzle size and the model. But not long before the problem started I successfully completed a tower print at 200mm/s with zero issues. It should be noted, though, that once again this is an issue happening outside the realm of print settings.

Super bizarre…

Any chance there’s some mechanical damage to the thermistor? If you’ve rebuilt the hotend a bunch of times it’s really easy to do, I’ve totally reefed down on a setscrew before and flattened one, could lead to it possibly reporting a wrong value, a crack + high vibrations during printing + thermal cycling could lead to it getting worse over time. Sudden shifts to me would suggest a problem with the thermistor itself, especially given the total overhaul you’ve done. As crappy as it is too, if I recall electrical components often follow an early failure pattern where they can have a higher failure rate at beginning of life and then drops off, for the price of thermistor cartridges it’s not a bad idea to keep some on hand just in case.

To make your life easier, Do you have a molex connector at the hotend? A lot of thermistor cartridges come with short leads and a molex connector, makes swapping them so much easier. If you don’t already have some crimpers, Engineer PA-09 is a solid pair that’ll do everything from molex to jst.

Thermistor swap was done a few times on the old board when the same issue was happening. I had 3 of them that I was swapping between.

Currently in there is a pretty nice thermistor that, rather than using a set screen to keep it in place, is actually built in to the end of a set screw; it’s effectively impossible to damage it. Unfortunately, it’s a known-good resistor, my problem lies elsewhere.

Wow yeah, that’s even more annoying then. Last ditch thing to me would be to check the resistance across th0 and compare to thb, I got ~6.28 kohms on both checking a spare board, just super strange this happened so suddenly.

Good call on checking that resistance, didn’t think of that before.

Even more frustrating is it happening twice across two different boards!